Metal Detectors

I've recently been on holiday in NSW, and my uncle gave me a pile of sapphire bearing gravel which he'd added gold to. I had lot of fun sifting through it and I'd love to go back and collect more of the stuff.

I got the impression that the minerals in the gravel would glow under UV light, so I bought a UV flood light and some electronics to make a UV strobe. I could use the strobe to tell me if I'm digging in the right place. Only 1% of the bits of gravel glowed under the spotlight so that was a bust.

I'm also thinking of looking for gold. I've been thinking a lot about how I could make my own metal detector.

I purchased a solder-your-own metal detector kit, MDS-60, and it's not great. I could detect a 5c coin from around 5mm. It's a start, but I'd like to build a metal detector that can compete on sensitivity to small pieces of gold as an expensive unit.

Here is a video of the device in action

With a bit of fine tuning I was able to achieve detection at about 1cm.

All for now, Boston

Update 4/3/2025:

MDS-60 Metal Detector Kit

The MDS-60 is a very simple solder-your-own metal detector kit. It only has 3 active components: two PNP transistors and one NPN transistor (don't get these mixed up!). I'm impressed with how well this works for such a simple design.

The device shows a positive response to a 5c coin at around 2cm, and a strong negative response to ferrite.

Here is the best circuit diagram I've seen online:

I believe the circuit detects metal based on changes in the Q-factor of the resonator formed by the inductor coil (L1) and various capacitors. Positioning a conductor near the coil will lower the Q-factor and positioning a ferrite near the coil will raise the Q-factor. A resonator with a low Q-factor dissipates energy more quickly than one with a high Q-factor. Thus, more current is needed to drive the circuit. This current is detected, amplified and sent to the output.L1 is a coil of wire etched directly into the two-sided PCB. As well as the main winding, it has an extra loop that connects to C2 in the diagram above. I have seen suggested that the coupling between the extra loop and and the main winding is used to detect pieces of metal nearby, but I like the the Q-factor explanation better. The extra loop provides feedback which is amplified and sent back into the main winding.

All for now, Boston.

Radio-Kit M185.2v1

I have assembled a metal detecting probe using the Radio-Kit M185.2v1

When assembled with a 20cm coil, the device was sensitive to a 5c coin at 10-15 cm, and not sensitive to 3mm gold. When assembled with the probe, the device was sensitive to a 5c coin at about 2cm, and sensitive to 3mm gold at about 1/2 cm. I hope to go down to the creek and poke around under rocks with it. Maybe I can optimise the probe by increasing or decreasing the number of coils or removing the ferrite

Pulse Induction metal detectors usually create a magnetic pulse and then sample the signal a moment later as it takes time for the pulse to decay (having metal near the coil slows down this decay time due to energy being stored in eddy currents within the metal). What is interesting is that this circuit uses only one 555 chip for timing and only 2 op amps. The design is based on the widely available Pirate Metal Detector design. (I guess) the circuit works by filtering the signal across the coil, integrating over the time it takes for the signal to decay.

All for now,

Boston

Update 28/4/2025

I made a new probe with insulated wire for the coil and coaxial cable to connect to the pcb. The old probe used magnet wire and audio cable. I did this to reduce the capacitance of the probe. I have read that having less capacitance helps with a PI design.

I tested both probes. The old probe picked up a 5c coin from 1cm away, and did not pick up a 3mm piece of gold. The new probe picked up a 5c coin at maybe 1.5 cm, and did not pick up a 3mm piece of gold.

I think if you improve the capacitance, you also need to vary the damping resistor, or you can experiment with changing the inductance. I will experiment with varying the number of windings in the coil, some other time.

Boss

Update 18/5/2025 - Induction Balance

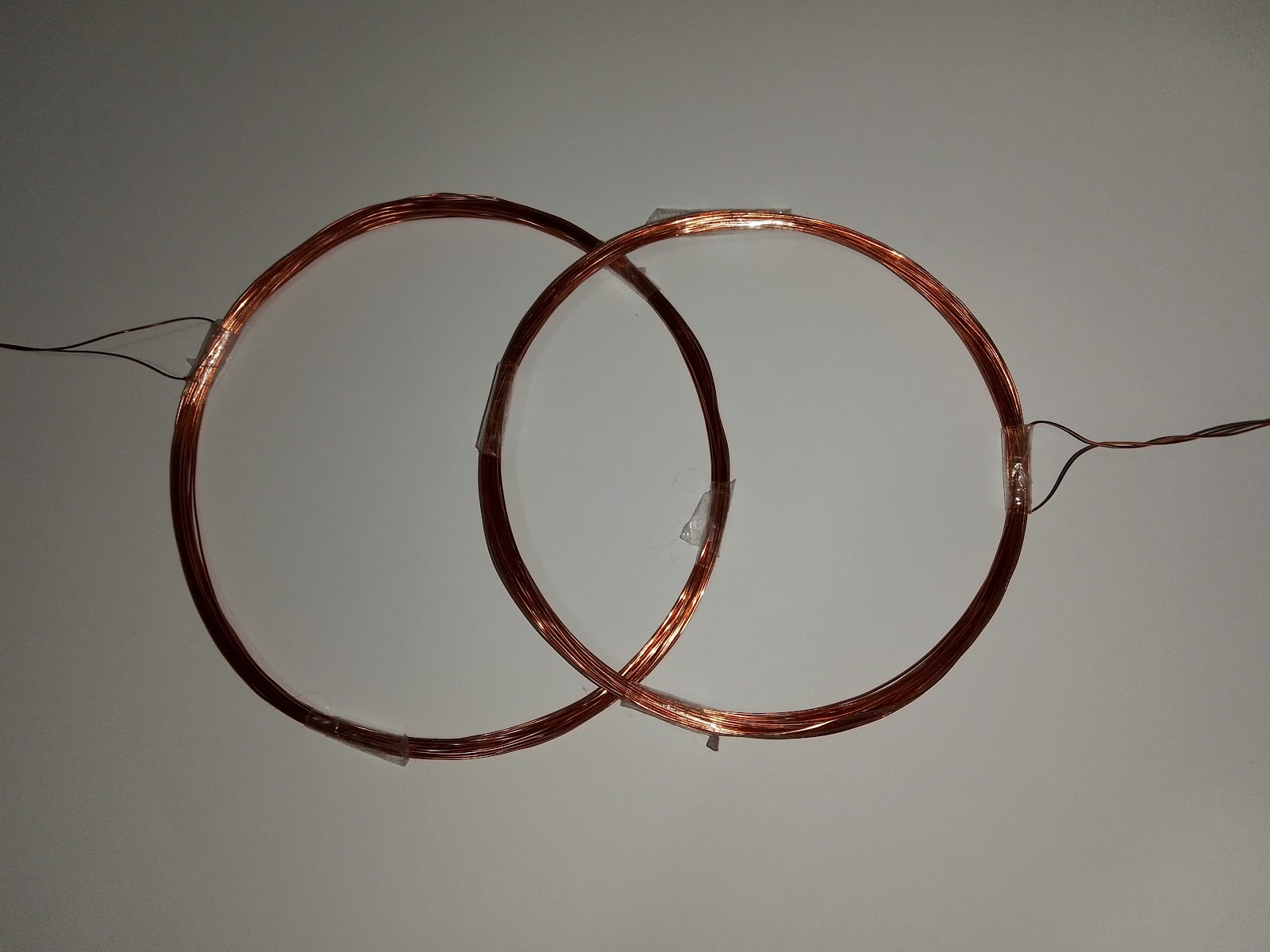

I've successfully demonstrated the principle of an induction balance metal detector. I connected one coil of wire to a signal generator and another to an oscilloscope.

Here we see the coils fully overlapping, and the signal on the oscilloscope:

We see that the EMF from the region where the receiver coil is overlapping transmitter coil cancels with the EMF from the region where they are not overlapping.

Here the coils are fully overlapping:

Here we have induction balance:

It feels good to get stuff done. I'll be going to Lightning Ridge in two weeks to poke around for opals.

All for now, Boston.

PS Today I tried to detect smaller objects but the circuit behaved like it had a few loose wires.

Update 21/5/2024

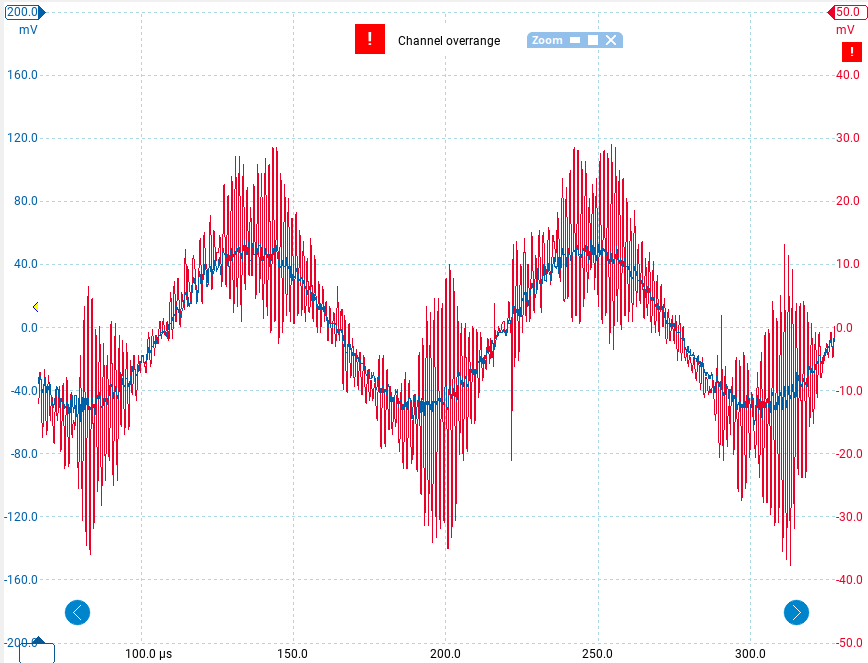

I've rebuilt the circuit on a different breadboard. The signal on the receiver was fuzzy from high frequency noise. I replaced R7 with a 15 ohm resistor and started getting a better signal:

I used a figure-eight coil to reduce EMI, zoomed in on the oscilloscope, and created an induction balance:

There is some signal there, if you use your imagination, but it was hard to maintain the induction balance anyway. I can identify 3 sources of improvement for this circuit: use a PCB rather than a bread board to minimise the area susceptible to EMI, use a more expensive op-amp (than NE5534P Low Noise High Speed Op-Amp Linear IC), or use a more professionally made coil arrangement.

That's as much experimenting with this circuit I will do now,

Boston

PS don't leave batteries in a battery holder with loose wires, when not in use. It will short circuit and melt:

Update 21/5/2024 Pulse Induction:

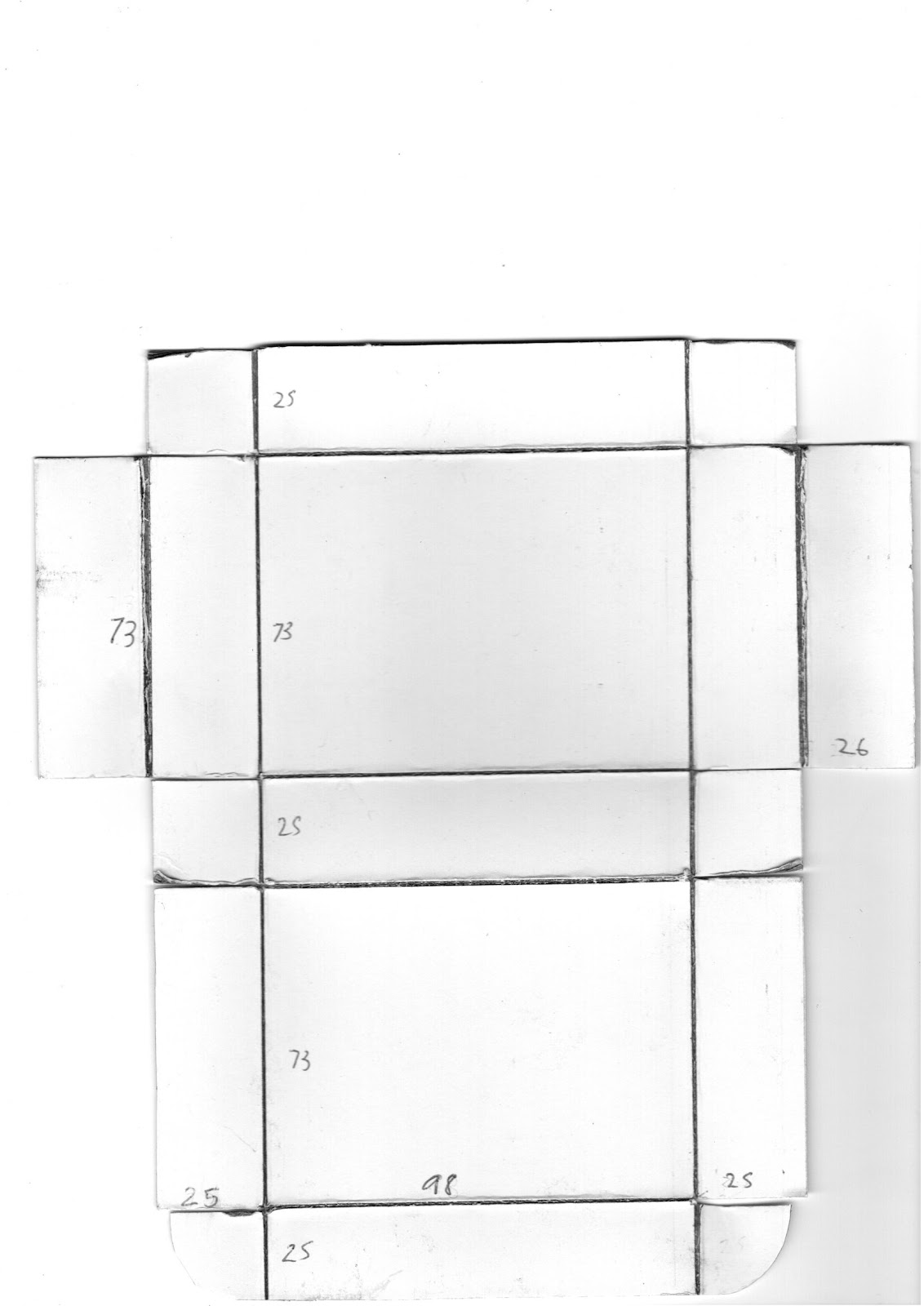

A bit of an escalation from the previous circuit, I plan to make the analog front end of a pulsed induction type metal detector:

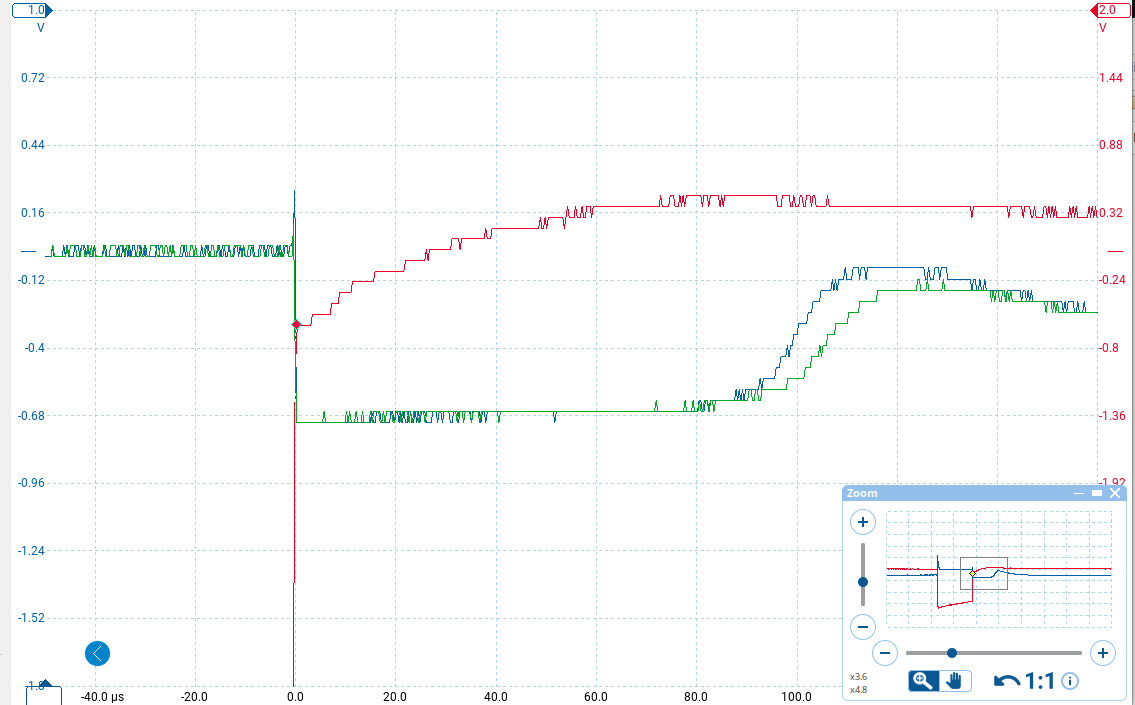

The signal coming in on the left hand side of the image should look like this:

A period of 1.5ms gives a frequency of about 666Hz and an on time of 100µs gives a duty cycle of about 6.5%

Here is the breadboard:

I am a bit worried about the flimsy attachment of the voltage regulator ICs since they're not being potted:

For smaller signals, when the probe was further from the metal detector's coil, the waveform looked more triangular. For larger signals, the waveform looked more like a square wave, so there is a problem with linearity. I believe the real signal is a sine wave. I didn't have a 47pf capacitor so I used a 33pf and a 10pf in parallel, and I am using whatever high bandwidth op-amp they were selling in Jaycar, so that might explain it. The frequency is about 45khz.

Comments

Post a Comment